I some how missed these messages but here's a late reply.

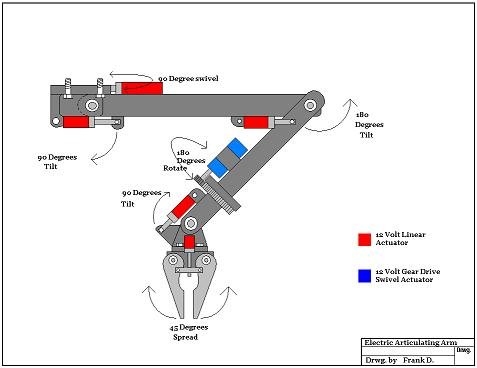

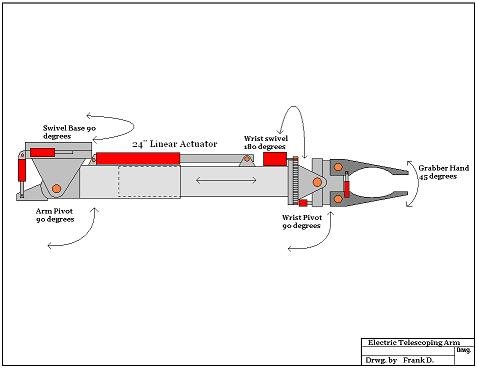

I had done some concept sketches for manipulator arms using electric

actuators so I thought I'd put them up.

Where I have shown electric linear actuators a person could substitute

small hydraulic cylinders or even air cylinders.

I'm still holding out to see if Vance has made any progress on his

"cue-ball" manipulator grabber.

These quick sketches were just to see how many joints would be required and

what type of actuators, be it linear or rotating types.

It looks like it takes a minimum of 6 joints to attain full movement.

Many different materials can be used for the structural elements. I lean

more toward aluminum because it can be purchased as extruded shapes in almost

any form and it's easy to cut, drill, and fab with minimal tools. The strength

to weight ratio is good and corrosion is dealt with easily.

Other materials could include stainless, and even PVC.

Just a little food for thought.

Frank D.