|

Sorry for the delay....the power has been out again so no computer or

welding/grinding. Very frustrating.

Congratulations on your test Jim. It sounds like you're making great

progress !

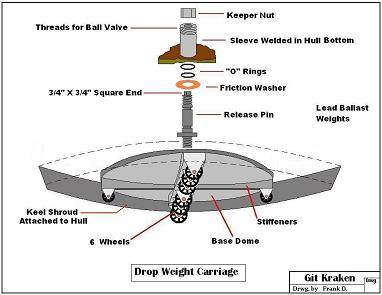

I too have been making my drop weight assembly.

I had originally planned on just a hydraulic release catch, but

have changed it to a threaded pin as a fail-safe.

The pin has a 3/4" square on the upper end which is accessed by opening a

2" ball valve in the hull bottom.

By opening the ball valve and inserting a square socket over the square

ended pin, I can rotate the pin so it "unthreads" from the nut on the drop

weight pan. The pin stays in the sleeve, and the pan drops off.

The pan is actually the round disk I cut out from the hull for

the hatch. It's curvature matches the hull bottom exactly so the release

pin acts like a big bolt pulling the pan up tight to the hull bottom.

The pan is also the base for the rollers on the sub. I have put 6 steel

wheels rated at 1500 lbs. each in a row on the bottom of the pan, to act like a

large roller so the sub can be rolled or spun while on the shop floor.

The two smaller wheels in front and behind the main roller wheels will

steer the sub straight if either one is touching the floor. Because these two

wheels are slightly smaller, the sub will "teeter" on the main rollers.

I will be adding a 1/4" steel shroud to the hull bottom so any contact with

rocks or sea weed will not hit the drop weight pan/wheel assembly.

Here's a little sketch.

The 4 lead weights ( not shown ) will be triangular blocks bolted to the

steel pan.

For this assembly to work properly the sub will need to be balanced at the

center point.

Frank D.

|